BRAKE LINING REVETING MACHINE-FOOT OPERATED

BRAKE LINING REVETING MACHINE-FOOT OPERATED Specification

- Features

- Sturdy Construction; Easy Operation; Replaceable Dies; Adjustable Table

- Power Type

- Manual Foot Operated

- Weight

- Approx. 80-100 kg

- Model No

- BLR-F (Foot Operated)

- Assembly

- Ready to Use/Minimal Assembly Required

- Size

- Standard (Custom Sizes on Request)

- Style

- Foot Operated

- Use

- Brake Lining Riveting for Automobiles and Industrial Applications

- Surface Finish

- Powder Coated/Enamel Painted

- Type

- Mechanical Riveting Machine

- Material

- Cast Iron Body with Steel Components

- Dimensions

- Approx. 500 mm x 300 mm x 1,100 mm

- Shape

- Vertical Floor Mounted

- Color

- Industrial Green/Blue (subject to stock)

- Function

- Riveting and Removing Brake Linings

- Age

- Suitable for Workshops, Garages, and Maintenance Facilities

- Advantage

- Manual Foot Operation - No Electricity Required

BRAKE LINING REVETING MACHINE-FOOT OPERATED Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Letter of Credit (L/C), Delivery Point (DP), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Months

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About BRAKE LINING REVETING MACHINE-FOOT OPERATED

Model No. MT-Z37

BRAKE LINING REVETING MACHINE-FOOT OPERATED

Foot Operated Brake shoe riveting machine for brake shoes and for clutch discs for cars, vans. It is perfect for rivet brake shoes and clutch discs of any kind of vehicles since there is enough space between the tool and die punch.

The riveting machine has a new innovative die-punch base that creates a perfect holding and grip, with which possible deviations or imbalances in the riveting process and the brake shoe coverings are avoided

Technical Specification

Maximum distance from the die holder to the back die 40 mm.

Min. distance from the die holder to the back die 0 mm.

Max. stroke 30 mm.

Punches bases kit for riveting tubular and semi-tubular rivets of warm material: 4, 5, 6, 8,10 mm.

Efficient Foot-Operated Riveting

The BLR-F foot-operated rivet machine streamlines the process of brake lining attachment, offering mechanical advantage through a robust pedal mechanism. Its vertical design and adjustable table provide optimal working height and comfort, making long shifts more manageable for operators. Specially designed to handle rivet sizes between 3 mm and 8 mm, it ensures secure and accurate rivet placement every time.

Durability and Reliability

Built from premium cast iron with steel components and finished in industrial-grade powder coating or enamel paint, this machine is made to withstand heavy, continuous use. Lubrication points are provided for smooth motion and prolonged machine life. Replaceable dies and low-maintenance design reduce downtime and simplify upkeep.

Ready for Workshop Use

Packed securely in a wooden box or carton, the BLR-F arrives ready to use with minimal assembly. Accessories include a full set of standard riveting dies, allowing immediate start-up. Its compact dimensions and manageable weight enable straightforward installation in various locations, from small garages to large maintenance facilities.

FAQs of BRAKE LINING REVETING MACHINE-FOOT OPERATED:

Q: How do I operate the BRAKE LINING RIVETING MACHINE-FOOT OPERATED?

A: Simply position the brake lining and the desired rivet size in the machine, select the appropriate die, and use the foot pedal to apply mechanical force for riveting. The adjustable table and ergonomic pedal placement make operation straightforward and efficient.Q: What is the range of rivet sizes supported by this machine?

A: The machine is compatible with rivets ranging from 3 mm to 8 mm in diameter, covering most standard brake lining applications in both automotive and industrial sectors.Q: When should I perform maintenance on the BLR-F machine?

A: Routine lubrication at designated points is recommended to keep the mechanism running smoothly. Other than regular cleaning, the machine is designed to be low maintenance and features easily replaceable dies for prolonged usability.Q: Where can the BLR-F machine be installed?

A: This mechanical riveting machine can be installed in workshops, garages, maintenance facilities, or industrial plants. Its floor-mounted vertical design and moderate footprint allow versatile placement in most workspaces.Q: What process does the machine use to rivet brake linings?

A: The operator manually places the brake lining and rivet in the machine, then presses the foot pedal to activate the riveting mechanism. The mechanical advantage from the pedal delivers consistent, secure rivet installation or removal.Q: What are the benefits of using a foot-operated riveting machine over electric models?

A: Manual foot operation requires no electricity, offering enhanced safety and portability. It is ideal for areas without reliable power supply and reduces operational costs while maintaining high productivity.Q: Is the BLR-F suitable for various brake lining sizes and custom orders?

A: Yes, while the standard model fits most applications, custom sizes can be requested from the manufacturer to accommodate specific needs or larger brake lining dimensions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool And Equipments Category

TYRE CHANGER

Price 200000 INR

Minimum Order Quantity : 1 , , Unit

Color : Red/Black

Material : Highgrade Steel

Shape : Rectangular Base with Vertical Arm

Advantage : Fast and Easy Tyre Changing; Suitable for All Tyre Types

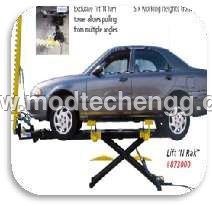

CAR CRASH EQUIPMENT CHASSISLINER - LIFT N RAK

Price 200000 INR

Minimum Order Quantity : 1 Unit

Color : Red / Silver

Material : Highgrade steel chassis

Shape : Rectangular frame with hydraulic lift arms

Advantage : Convenient 360degree access, easy positioning and lifting, fast setup

AC SERVICE STATION

Price 20000 INR

Minimum Order Quantity : 1 Unit

Color : Blue and Black

Material : Metal Body with ABS Panel

Shape : Rectangular Cabinet

Advantage : Efficient, Easy to Operate, Reduces Manual Work

VIDEOGRAHIC WHEEL BALANCER

Price 2000 INR

Minimum Order Quantity : 1 , , Unit

Color : Grey/Blue

Material : Highquality steel and plastic components

Shape : Rectangular base with circular wheel mount

Advantage : Digital videographic display for accurate measurement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS