TRAINING PLATFORM FOR ABS BRAKE SYSTEM

Product Details:

TRAINING PLATFORM FOR ABS BRAKE SYSTEM Price And Quantity

- 2000 INR

- 1 Unit

TRAINING PLATFORM FOR ABS BRAKE SYSTEM Trade Information

- Western Union Paypal Cheque

- 100 Unit Per Week

- 1 Week

- Australia Central America North America South America Eastern Europe Middle East Western Europe Africa Asia

- All India

Product Description

TRAINING PLATFORM FOR ABS BRAKE SYSTEM.

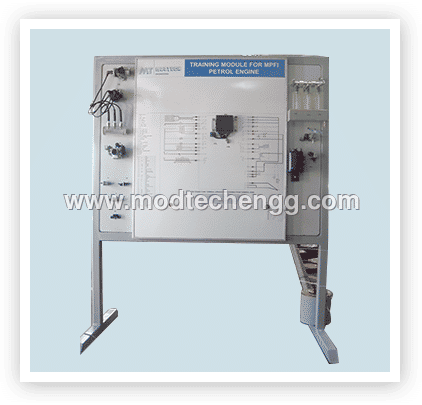

The device is designed on the ABS system, where in the principle of operation and working of the same can be demonstrated . A parts and accessories are arranged on to a Colour printed board. And the system is made functional.

Features

Real and operatable ABS brake system is assembled onto a colour printed board to illustrating the structure and working process .

The front and rear Disc Brake with callipers are coupled to two different three phase motor with electric drives to rotate the front disc and rear disc separately. A brake

Pedal along with vacuum booster is connected to the Front calliper system and rear drum brake system, a vacuum pump will be connected to the booster to demonstrate the effect of vacuum in the pedal operation.

The Device is connected with Pressure meters to demonstrate the different pressure at different locations in the brake system.

Coloured circuit diagram on the training Module printed on to 6mm organic glass base. Where in the students can compare the diagram and actual diagram.

Detection terminals for operator to detect various sensors, actuators, electrical signals for engine control unit, such as resistive, voltage, current , frequency and wave form signals are provided on to the printed circuit diagram.

The training module is fitted with diagnostic socket (DLC) for universal automobile decoder (Scan tool) to read fault codes, clear fault codes and read data stream.

Fault setting switch bank will be provided to induce faults in the training module to demonstrate the fault and to diagnose faults.

Set the line break, grounding short circuit, improper contact or open circuit faults can be induced, user can adjust the number and type of faults.