Training Platform For Abs Brake System

Training Platform For Abs Brake System Specification

- Size

- Standard / Customizable

- Surface Finish

- Powder Coated, Corrosion Resistant

- Style

- Training Platform, Floor Mounted

- Power Type

- Electric, Single Phase 230V AC

- Weight

- Approx. 105 kg

- Type

- Automotive Training Equipment

- Material

- Mild Steel, Transparent Acrylic Panel

- Dimensions

- 1500 mm x 800 mm x 1800 mm

- Shape

- Rectangular Base with Mounted ABS System

- Color

- Silver, Grey, Transparent Panel Sections

- Function

- Demonstration of ABS Brake System Components and Operation with Fault Simulation

- Age

- For Technical Students / Trainees above 16 years

- ABS Components Included

- Master Cylinder, Wheel Sensors, Hydraulic Modulator, Control Unit, Pedal Assembly

- Mobility

- Wheeled for Easy Relocation

- Safety

- Overload and Short Circuit Protection

- Demonstration

- Live ABS Activation, Standard Braking vs ABS, Fault Diagnosis

- Educational Support

- Comes with Training Manual and Circuit Diagrams

- Control Panel Features

- LED Indicators, Fault Switches, Simulated Sensor Inputs, Power Controls

- Operation Mode

- Manual and Automatic Demonstration Modes

Training Platform For Abs Brake System Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Western Union, Paypal, Cheque

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2 Months

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

About Training Platform For Abs Brake System

The device is designed on the ABS system, where in the principle of operation and working of the same can be demonstrated . A parts and accessories are arranged on to a Colour printed board. And the system is made functional.

Features

1. Real and operatable ABS brake system is assembled onto a colour printed board to illustrating the structure and working process .

2. The front and rear Disc Brake with callipers are coupled to two different three phase motor with electric drives to rotate the front disc and rear disc separately. A brake

Pedal along with vacuum booster is connected to the Front calliper system and rear drum brake system, a vacuum pump will be connected to the booster to demonstrate the effect of vacuum in the pedal operation.

3. The Device is connected with Pressure meters to demonstrate the different pressure at different locations in the brake system.

4. Coloured circuit diagram on the training Module printed on to 6mm organic glass base. Where in the students can compare the diagram and actual diagram.

5. Detection terminals for operator to detect various sensors, actuators, electrical signals for engine control unit, such as resistive, voltage, current , frequency and wave form signals are provided on to the printed circuit diagram.

6. The training module is fitted with diagnostic socket (DLC) for universal automobile decoder (Scan tool) to read fault codes, clear fault codes and read data stream.

7. Fault setting switch bank will be provided to induce faults in the training module to demonstrate the fault and to diagnose faults.

8. Set the line break, grounding short circuit, improper contact or open circuit faults can be induced, user can adjust the number and type of faults.

9. Good working condition Parts will be provided with fuel tank. The instruction board has to be connected to 220V AC socket Which changes to 12V DC internally, so that the board works without battery.

10. The training module is fabricated using steel pipe frame with spray painted for good looks and the entire setup is provided with caster wheels with brakes for easy movement of the same.

Complete Hands-On Learning Solution

This training platform offers a realistic and comprehensive learning environment, allowing technical students to explore ABS brake system operation and diagnostics hands-on. The inclusion of real components, transparent panels, and simulation controls enhances concept clarity and practical understanding of automotive safety systems.

Interactive Features for Effective Training

With live ABS activation, clear LED status indicators, and fault insertion switches, trainees can manually or automatically operate the system. Comparative demonstrations between standard braking and ABS responses, alongside fault diagnosis capabilities, ensure an immersive experience that builds both knowledge and troubleshooting skills.

Designed for Convenience and Durability

Constructed from corrosion-resistant mild steel and finished with powder coating, the sturdy, floor-mounted platform balances longevity with ease of mobility, thanks to integrated wheels. Transparent acrylic panels provide visibility into system workings, while overload and short-circuit protection guarantee safe operation during sessions.

FAQs of Training Platform For Abs Brake System:

Q: How does the ABS Brake System Training Platform help in understanding modern automotive braking systems?

A: The platform provides real automotive ABS components, enabling students to observe standard and ABS braking operations side by side. Live demonstrations, sensor simulations, and transparent panels deepen understanding of system behavior, diagnosis, and troubleshooting, crucial for todays automotive technicians.Q: What is included in the ABS Training Platforms package?

A: The package comprises a master cylinder, wheel sensors, hydraulic modulator, control unit, pedal assembly, control panel with LEDs, fault switches, simulated sensor inputs, and safety features. It also includes a detailed training manual, full circuit diagrams, and a wheeled powder-coated frame for mobility.Q: When is this training equipment typically used during a technical program?

A: It is ideally integrated into automotive courses when students are introduced to vehicle braking systems, safe driving technology, or diagnostic procedures. The platform is suitable for hands-on labs, demonstrations, skill assessments, and advanced troubleshooting practice.Q: Where can the ABS Training Platform be installed?

A: Designed for floor mounting, the platform is suitable for automotive labs, training centers, technical institutes, and vocational workshops. Its standard or customizable dimensions and mobility ensure it fits diverse educational settings and can be relocated easily as needed.Q: What is the process for demonstrating fault diagnosis on this platform?

A: Instructors or students can activate fault switches or simulate faulty sensor inputs to replicate real-world ABS issues. The systems LED indicators and control panel display error conditions, guiding users through systematic troubleshooting procedures as outlined in the training manual.Q: How can trainees benefit from using this ABS Training Platform?

A: By interacting directly with real ABS components and simulation features, trainees gain problem-solving abilities and technical confidence. The platform enhances theoretical knowledge with practical skills, better preparing students for industry roles in vehicle diagnostics and repair.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut section Model Of Different Automobile Parts Category

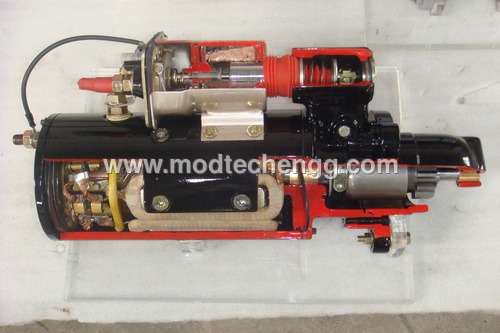

Motor Starter

Price 2000 INR

Minimum Order Quantity : 1 , , Piece

Weight : Approx. 820 g

Dimensions : 130 x 75 x 100 mm

Shape : Rectangular

Size : Standard

Working Demo Board Of CFDI System

Price 2000 INR

Minimum Order Quantity : 1 , , Unit

Weight : Approx. 1.2 Kg

Dimensions : 360mm x 260mm x 110mm

Shape : Rectangular

Size : Standard Training Board Size

Model of Car Rear Axle (Working)

Price 2000 INR

Minimum Order Quantity : 1 Unit

Weight : Approx. 2.8 kg

Dimensions : Approx. 350mm x 170mm x 190mm

Size : Medium

Cut Section Model Of Oil Pump External

Price 2000 INR

Minimum Order Quantity : 1 , , Unit

Weight : Approx. 1.8 kg

Dimensions : 30 cm x 18 cm x 15 cm

Shape : Rectangular base with cylindrical gear assembly

Size : Standard Laboratory Size

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS